Our Solution

Background

SkyWind will reduce cost and risk onshore and offshore. This is done by considering the total life span, including investments and operation and maintenance cost.

Where other turbines have been developed incremental since around 1980, SkyWind have asked necessary questions, based on operation of 250 different turbines.

Each element in the SkyWind solution is based on conventional technology, but put together in a new way.

SkyWind has also challenged the way a turbine is structured, with independent modules instead of smaller dependent parts. In addition the conventional way to install turbines has been challenged.

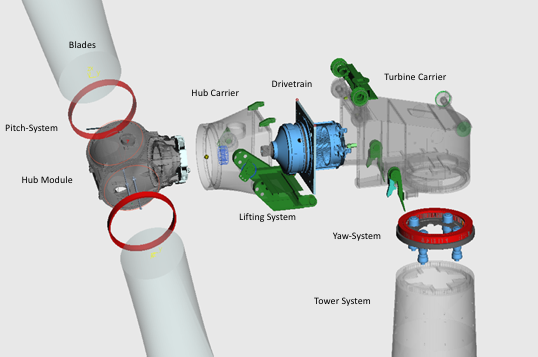

Modularized Concept

The SkyWind turbine is modularized. Each module can be fabricated separately based on exact specifications, and in operation each module is controlled such that input and output is monitored/recorded. Each supplier will then be responsible based on the specifications w.r.t. guarantees etc.

- Blades

- Hub

- Load carriers (replacing traditional nacelle)

- Tower system

- Lifting system

- Pitch system

- Yaw system

- Hydraulics

- Drivetrain

- Control system

- Grid connection unit

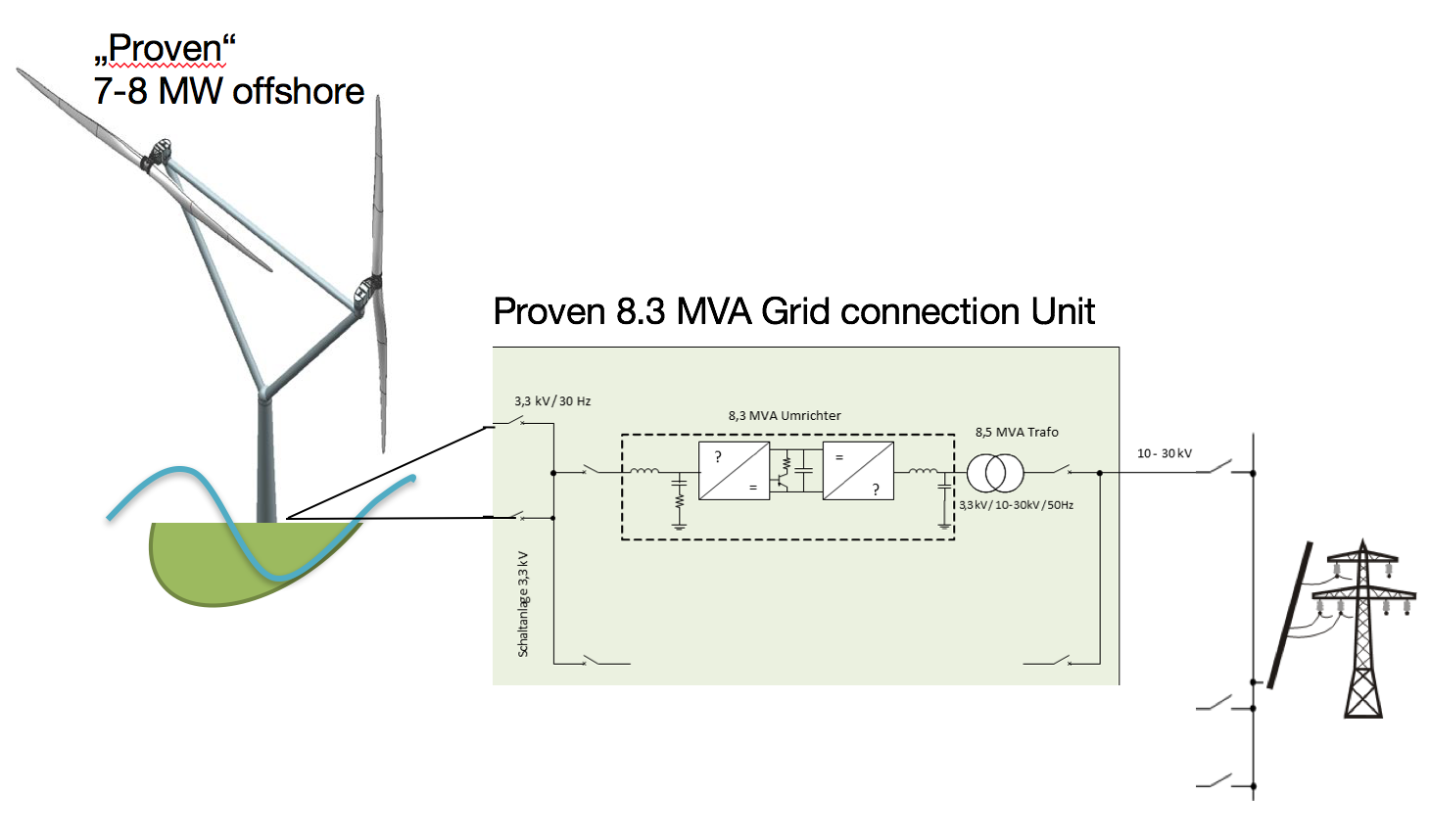

Electrical Systems – External Units

Normally, each turbine has its separate electrical system, and a turbine is therefore a power plant by itself. This is understandable for smaller units and form the starting point in modern wind turbines as it all started in the 1980s. But based on experience in larger wind farms, SkyWind has developed electrical systems based on external units.

There are several advantages with this:

- Lighter turbine

- Simplified O&M – can be done in one central unit

- More redundancy since the system is not depending on a particular electrical unit

- Higher utilization of each unit, less losses

Two Blades

It is well known that two blades give almost the same output as three blades. Utilizing the turbine 100% will give some more noise, but offshore this is a smaller concern.

The advantages with two blades are:

- Lighter, simpler solution (less cost)

- Enables new installation technology

- Enables a twin-rotor system (scaling up, see below) where the turbines can be closer together

Scaling Up

The costs of normal scaling up reach practical limits, and analyses show that a twin rotor concept will result in reduced cost compared to scaling up the turbine. In this way it will also be possible to use the same turbine, simplifying fabrication.

The onshore version (3.4 MW) is an optimized design, made as large as possible with given restrictions on transport and installation on shore.

SkyWind is developing a twin-rotor with a yaw system installed in the central tower unit. In this way two turbines can be installed on one foundation. The same basic SkyWind turbine is therefore suitable for both on and offshore wind.